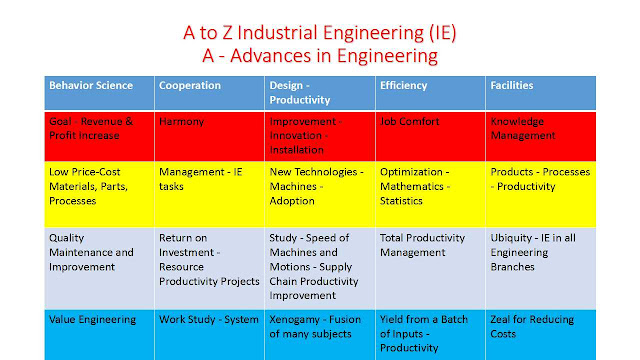

2025 - A to Z Industrial Engineering - Blogging Theme - Industrial Engineering Benefits the Society and Organizations

Industrial Engineering - Systems/Processes/Methods Improvement Using Engineering solutions creatively.

Industrial Engineering - Prime focus - Productivity Improvement.

Productivity improvement gives National Prosperity and Organization Prosperity.

Source: https://www.linkedin.com/posts/national-productivity-council-gandhinagar_cartoonseriesabr10-productivity-economicgrowth-activity-7301162658278379520-eyyl

A to Z of Industrial Engineering - Blogging Challenge April 2025 - Proposed Posts

https://nraoiekc.blogspot.com/2025/02/a-to-z-of-industrial-engineering.html

Existing Collection of Articles

A to Z of Industrial Engineering - Principles, Methods, Techniques, Tools and Applications

https://nraoiekc.blogspot.com/2018/06/a-to-z-of-industrial-engineering.html

Goals - Result Areas of Industrial Engineering

_____________________________________________________

Interpretation of IISE Definition

"Industrial engineering is concerned with the design, improvement, and installation of integrated systems of people, material, information, equipment, and energy. It draws upon specialized knowledge and skills in the mathematical, physical, and social sciences together with the principles and methods of engineering analysis and design to specify, predict, and evaluate the results to be obtained from such systems."

What are terms in the definition related to focus of the discipline?

Design, improvement, and installation of integrated systems of people, material, information, equipment, and energy.

To specify, predict, and evaluate the results to be obtained from such systems.

Specialized knowledge and skills in the mathematical, physical, and social sciences together with the principles and methods of engineering analysis and design.

What is core knowledge of Industrial Engineering?

Principles and methods of engineering analysis and design. - Principles and methods of engineering.

Additional knowledge to be used along with engineering.

Specialized knowledge and skills in the mathematical, physical, and social sciences.

Knowledge useful for industrial engineering.

What are activities of Industrial Engineering?

Design, improvement, and installation of integrated systems of people, material, information, equipment, and energy.

Installation includes production, construction, fabrication etc. engineering or engineered products and services.

What is the purpose of Industrial Engineering?

To specify, predict, and evaluate the results to be obtained from such systems.

Add improve (improvement of results).

Industrial engineers must be able to specify the results to be obtained from systems. (Requirement)

Industrial engineers must be able to predict the results to be obtained from systems. (given the design system).

Industrial engineers must be able to evaluate predict the results to be obtained from systems in operation.

Industrial engineers must improve the results to be obtained from systems in design stage or in operating stage.

What are important result areas - Focus of Industrial Engineering?

Cost

Productivity

Time taken by machines and men

Material consumption

Energy consumption

Information

Qualtiy - It is a constraint. IE should not result in lower quality.

Reliability

Delivery - Quanity produced as per demand.

Flexiblity

Sustainability

Interesting Comments on LinkedIn regarding "Goals - Result Areas of Industrial Engineering."

Comment by Jim Beckham

Retired Director, Total Quality Management at JTEKT Corporation

I find the comments on priority an interesting discussion point. Let me contribute from someone who worked 14 years at one of the Toyota group of companies. We only used the first four, in priority sequence, SQDC. But it’s important to understand which stakeholder is impacted by each:

Safety- Employee stakeholder;

Quality - Customer stakeholder;

Delivery - Customer stakeholder; and

Cost - Shareholder stakeholder.

When management, an improvement team or a QC Circle follows the 8-Step Problem Solving method to make an improvement to one of these four areas, the solution for the improvement can not adversely impact the areas above. For example it a team was trying to improve productivity (Cost) and the improvement would make it more dangerous for the workers, or create a quality defect, or impact delivery, then the team would have to find another solution.

Additional Comment by Jim Beckham, Retired Director, Total Quality Management at JTEKT Corporation

Just to be clear, an improvement could be made that adversely impacts an area below and that would ok. For example, when fixing a Quality problem the solution can’t adversely impact Safety (which is above), but it could adversely impact Cost or Delivery (which are below). This is ok. It then gives the improvement team motivation to then solve the secondary Cost or Delivery problem. A little pain is always a good motivator for teams to take ownership and to improve.

Post Included In

Modern Industrial Engineering - LinkedIn News Letter - May 2025 Issue.

Topic of Focus - Current Issues of Interest in Industrial Engineering to Make it Effective.

https://www.linkedin.com/pulse/current-issues-interest-industrial-engineering-may-2025-kvss-1hekc

------